|

Attaching Ordnance

by David

W. Aungst

HyperScale is proudly supported by Squadron

I like to build a certain amount of "survivability" into

my models.

I realized a long time ago that the models I build are

likely to be sitting on my display shelves for quite a few years. I will

regularly dust them. My kids will occasionally launch flying objects into

them. And, I will have to move them about from time to time. Building the

models so that these routine happenings do not cause damage keeps me

happier - I hate having to take time from the "current" model to fix a

broken model.

One of the more fragile components of most any aircraft is its weapons and

other ordnance. Bombs, fuel tanks, gun pods, rocket pods -- all are

usually only attached to the model at two tiny contact points. As they

normally get attached fully painted, the only glue that makes sense to use

on them is super glue. But, super glue is itself rather brittle and prone

to break easily under almost any shearing force. After getting tired of

continually re-attaching weapons to my models, I decided to find a better

way to do the attachments.

Building

some durable strength into the attachment points was what I needed. The

best answer I came up with was brass wire. Building

some durable strength into the attachment points was what I needed. The

best answer I came up with was brass wire.

A visit to a local hobby shop that deals mostly in train supplies revealed

some fine brass wire used for detailing model locomotives. The wire comes

in sizes all the way down to 0.005". That is practically as thin as a

human hair. In practise, I find that 0.010" brass is fine enough, but the

smaller size has uses.

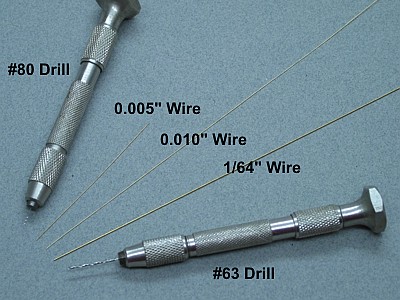

The picture to the right shows the tools and supplies needed for this

process. The two smallest wires are the train detailing supplies I wrote

about above. The larger wire is the smallest K&B brass wire, 1/64th inch.

The two needle vices show #80 and #63 drill bits, which pretty well match

the sizes of the brass wire.

-

I start the process by drilling holes in the weapons where

the attachment point are found. My example shows me drilling a painted

bomb, but in practise, I drill the weapons prior to painting. The wires

then become great hand-holds for holding the weapons while painting,

decaling, and weathering.

-

Once drilled, I insert a length of brass wire. I usually

use 0.010" diameter wire unless the weapon is very small, in which I will

use 0.005" diameter wire. Larger items like fuel tanks will get the 1/64th

inch size of wire. The limiting factor on choosing the diameter of wire is

the size of the mounting points. Very thin items will dictate the use of

finer wire. With all the weapons having the pins installed, I go on to

finish the painting, decaling, and weathering of the weapons.

-

Eventually the time to attach the weapons to the model

comes along. In my example, I attaching Mk82 Snakeye bombs on a Multiple

Ejector Rack (MER), then attaching the MER to the centerline pylon of an

A-4 Skyhawk. I hold the weapon in place and note the place where the wires

are contact with the mounting points. Then, I drill the first mounting

hole. Placing the corresponding wire of the weapon into the first mounting

hole, I pivot the weapon slightly so as to scratch the paint and mark the

location of the second hole. Then I drill the second hole.

Alignment of these holes is critical. If they are not spaced properly, the

wires mounted in the weapon will not fit into both holes. Also, if they

are not aligned with the centerline of the weapon, it will hang crooked on

the model. It takes some practise and a little "eyeballing" to get the

alignments to work.

-

With the holes drilled, I place a small drop of super glue

on the ends of the mounting wires and slip the weapon into place. It is

actually the wires that hold the weapon. The super glue only adds

stability to the fit. Now, if I bump the weapon, it might bend over, but

it will not break off. Then, I can just bend it back and have nothing to

fix!

A side benefit of this procedure is the near elimination of glue marks on

the weapons. Since the only glue used amounts to small beads placed on the

tips of the mounting wires that get shoved into locator holes on the

model, there is almost no visible glue on the weapons after attaching

them.

I have shown this process using aircraft weapons, but the

same procedure works on most any small item on any type of model. I do

this parts pinning on antennas, dump masts, canopies, and any other

attached protrusions to the model. As the wire is much stronger than the

plastic locator pins on weapons pylons, I sometimes will even cut away the

molded pins and drill mounting points to use brass pins on these, too.

The bottom line still comes down to "survivability". Being a little

ham-handed with the model may produce a bent over weapon or antenna, but

not a broken (and potentially lost) one.

Text & Images Copyright ©

2002 by David W. Aungst

Page Created 28 January, 2002

Last Updated

19 April, 2004

Back to Reference Library

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search