|

The Quest for an Air Compressor

by Glenn Irvine

HyperScale is proudly sponsored by Squadron.com

I built my first compressor from the guts of a home air

conditioner unit( I actually cut open the can and removed the compressor, this

was before I found out this was not necessary) but it had no pressure regulation

and was far too powerful for my Olympos Iwata HP-C. This was about 1976/7. As a

result I couldnít get the best from my airbrush and always thought it was the

brush, as I couldnít find anything wrong with the air supply. Because it was

constant and didnít appear too excessive.( remember, I was only 16-17). I later

was to sell the brush when I discovered cars as I thought I couldnít fix its

problems. I was able to successfully spray paint many models and paintings with

this set up, but the stoppages were too frustrating.

The

Importance of Regulation |

After re-discovering models and buying a S/H Badger 200, I needed another

compressor as I realised how important regulation of the air supply was. I

bought one of these and a friend had a diaphragm compressor that had seen better

days, which I also picked up cheap.

I was aware of the problems with pulsation with this type of

compressor so I sourced a S/H air tank from a truck wrecker and with a few

fittings, press regulator and some creative metalwork and paint I had a

serviceable compressor that served me well for 11 years. Its disadvantages were

its size and noise.

Building an

Airbrush Compressor |

Having moved into a smaller house much more restricted modelling space and a

family, I was relegated to airbrushing in the shed outside. This I found a bit

limiting, so I have always dreamed of a better compressor, I had an old article

on how to construct a compressor from a fridge unit, so I finally decided to do

so. I decided I needed a double action airbrush at about this time too, so I

treated myself to a new Iwata HP-B after I finished the compressor. (God, Iím

good to myself arenít I?)

I found a few used fridge compressors (free, they were at a scrap metal yard)

and after testing, selected one that seemed ok. This involved checking

compressor operation and especially, pressure. Remember they are being thrown

away for a reason.

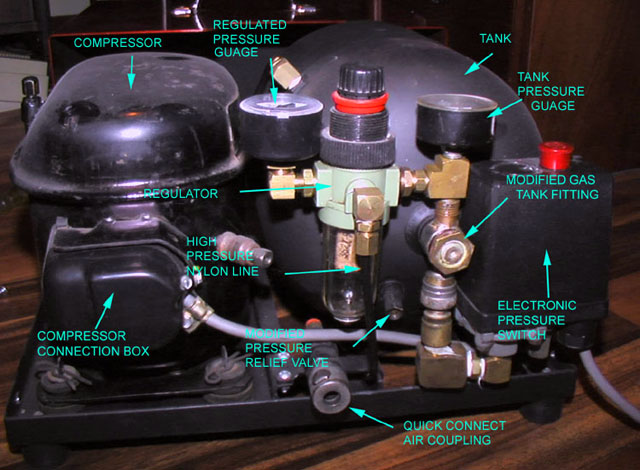

I then sourced a suitable reservoir; in my case it was a Primus gas bottle that

was flushed out with compressed air. The fitting was drilled out, being careful

not to damage the thread. The pressure relief valve was modified and adjusted to

blow off just over the cut off pressure of the pressure switch setting. A frame

was welded up from steel and the original compressor mounts from the fridge were

incorporated to simplify attachment. The tank had a couple of mounting tabs

braised to it and a hole drilled and a fitting braised to it to serve as the

input line.

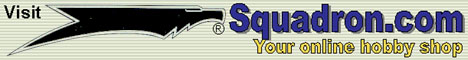

The compressor unit was modified to include a dipstick to check

and fill the oil and fittings silver soldered to the output line. An air filter

was coupled to the input line from a petrol filter and some rubber hose. The

unit and tank were coupled together using high pressure flexible plastic line

and brass fittings made up to adapt the gauges, press switch and outlet fitting

to the unit.

Finally rubber feet were fitted to the frame and a metal cover bent up and

welded at a sheet metal fabricator. This was then given a coat of Candy Apple

red (!) (left over from my car building days) and fitted with a handle. It

performs perfectly and is very quiet, so now I can airbrush inside at night

without waking everyone up.

I must point out that building this required quite a bit of

engineering and tools/equipment that most people may not have, also familiarity

with electronic circuits was also required. I would not recommend this to anyone

who is not familiar with the basics of an engineering workshop and circuitry, as

the end result may not be safe.

Also, be aware that because the compressor unit IS second hand,

there is a distinct possibility that it may have to be replaced at some stage,

so keep a couple of spare compressor units some where safe, just in case.

Cost was limited to a pressure switch, two gauges, a regulator

with filter, several brass fittings, some flexible high press line, 4 rubber

feet, some bolts and nuts, a quick release air coupling , a handle and the metal

case.

Text & Images Copyright © 2001 by

Glenn Irvine

Page Created 21 October, 2001

Last Updated

19 April, 2004

Back to Reference Library

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search