F-111 in Detail

Part One - Inlets

by Jim Rotramel

|

|

|

General Dynamics F-111A

A pair of Combat Lancer F-111As are shown with a pair of under-fuselage

AN/ALQ-87 ECM pods and weapon bay M61 gun installation. Note that there

was only a UHF antenna under the nose and the unusual shape of the

outboard weapon pylon. |

HyperScale is proudly supported by Squadron

My fellow modelers have often expressed amazement that while I

have over 1,000 hours flying F-111s, I donít have a model of one (other than

company models). I probably should have built the Hasagawa 1/72 scale kits,

which are pretty good (except for the Pave Tack pod).

But the focus of this series of articles is the 1/48 scale

Minicraft kit. While it captured the external shape of the aircraft, it has many

faults. Iím going to show the real jet through a modelerís eyes.

Iíll address the existing aftermarket kits that Iíve seen and

give you an honest appraisal of what I think about them. Unfortunately, to do a

really accurate kit is going to cost you about four to five times the cost of

the kit in resin. One can only hope that maybe Trumpeter will attack this

subject at some point.

IMPORTANT!!

If

you are like me, you like to look at the photos and skip the text. However, there

are a lot of important tidbits in the text of these articles!

Inlets

By FAR, the worst error in the Minicraft kit was the engine

inlets. Neither inlet style depicted by the kit even remotely captured the feel

of the actual articles.

Operational F/EF-111As, F/RF-111Cs, the first FB-111A (67-0159),

and the canceled F-111Ks were fitted with Triple Plow I inlets, which featured

hydraulically translated cowls.

The remaining FB-111A/F-111Gs, as well as all F-111D/E/Fs were

fitted with Triple Plow II inlets, which featured three Ďblow-iní doors. This

redesign increased the separation between the inlets and fuselage, removed the

external splitter panel, and featured inlet spikes 18-inches longer than the

Triple Plow Iís. The fuselage of Triple Plow II aircraft angled back ever so

slightly at the inlets to create more room between the two structures. These

aircraft also featured a small, round inlet between the engine inlet and the

fuselage. Finally, the F-111D/E/F and FB-111A all had a pattern of gray, and/or

fiberglass-brown panels of radar adsorbing material (RAM)

on the interior of their inlets.

A couple of ďspecial casesĒ: The second FB-111A (67-0160) was

fitted with Super Plow inlets, which were similar to the Triple Plow II except

that the translating cowls were replaced with two Ďblow-iní doors instead of

three. The first five F-111Bs (151xxx) were fitted with essentially Triple Plow

I inlets, while the last two (152xxx) had essentially Super Plows. Refer to the

Ginter Book on this subject for details.

While the Triple Plow II inlet reportedly increased inlet area

by ten percent, itís unclear if that was precisely true. Measurements of the

inlets suggest the TP II may be marginally larger than the TP I, but

nothing like ten percent. However, the frontal area of the inlets may have

increased by that much because of the shifting of the inlet farther out from the

fuselage.

Prior to engine start, the TP II blow-in doors (or TP I movable

cowl) were closed, opening as the engines powered up and sucked open the blow-in

doors (or the cowls opened). They remained open until after takeoff, when

sufficient air could be provided by the intakes alone. After landing they again

opened to increase the air available to the engines during ground operations.

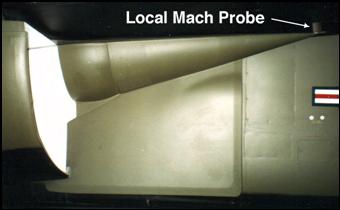

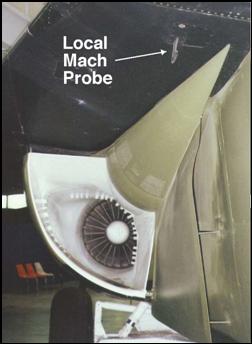

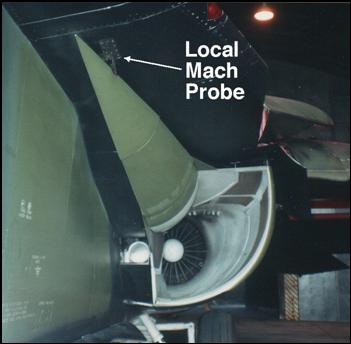

Triple Plow I inlets (left) were most easily distinguished

by the large splitter panel. Note how the inlet spike barely reached the local

Mach probe. Triple Plow II inlets (right) eliminated the splitter panel and the

inlet spike was 18 inches longer than on the earlier inlet, extending well past

the local Mach probe.

This view of the TP I inlet on the left clearly shows the

warped shape of the splitter panel and the lack of inlet RAM. Note how far

inboard of the local Mach probe the spike is. The TP II inlet on the right shows

how far outboard the inlet was shifted (note how close the it is to the local

Mach probe), the length of the inlet spike, and the inlet RAM.

The TP I translating cowl (left) and the triple blow in

doors of the TP II inlet (right).

Note: No aftermarket correction sets have been produced to correct

this serious error, although Scaledown has it on their list of things to do. In

addition, theyíve promised seamless intakes at some point as well.

Text Copyright © 2002

Jim Rotramel

Images Copyright © 2002 United States

Department of Defense and Jim Rotramel

Page Created 07 March, 2002

Last Updated

15 December, 2003

Back to Reference Library

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search