|

Focke-Wulf Fw 190

Main Landing Gear

Part One - Overview and

Operation

by

Robert Stephenson and

E. Brown Ryle III

HyperScale is proudly supported by

Squadron.com

Bob Stephenson and I have been emailing each

other for what seems a very long time. The text is usually split

between the general stuff of life and hobby related material.

Somewhere

among the email Bob mentioned a series of Internet postings on 1/48th

scale Fw190 landing gear asking the question “Which Fw190 stance

is correct? Is it the Trimaster, the DML/Dragon, or the Tamiya?”

According to Bob, the posted answers were more dependent on the

person’s opinion of the model than the study of Fw190 landing gear.

I knew why

there were numerous questions about the stance of the Fw190.

The Fw190 landing gear is not as easy to understand as it appears.

Bob and I

decided to do some research to see what answers we could sort out

regarding these questions. We hope the following will be a good

primmer on understanding both real and 1/48th scale Fw190

landing gear. Please note the changover from my part describing the

actual aircraft gear to Bob’s part of describing and detailing the

nature the model kit gear.

Overview &

Operation

The Fw190 undercarriage is a bit different from the average

fighter landing gear of its time. The Fw190 gear was: operated by

pushbutton control of electric motors in the wings, possessed

electric up- and down-locks, and had a control wire running from the

starboard strut that retracted the spring-loaded tail wheel. The

“look” of the gear is also different: when the gear is extended it

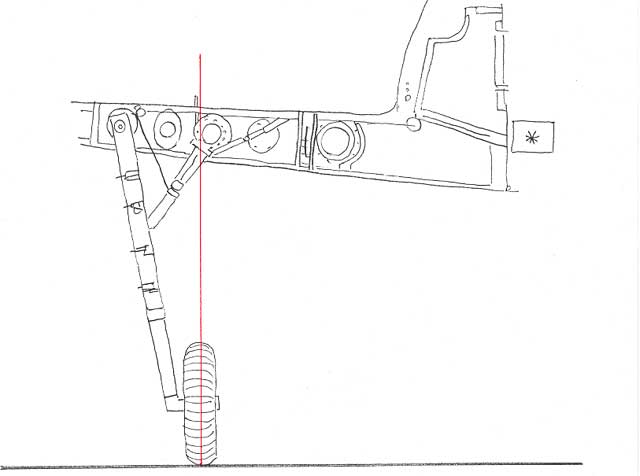

has an odd inward cant (Photo 1 below).

Noticeably, all of the tire is positioned forward of the leading

edge of the wing (Photo 2 below).

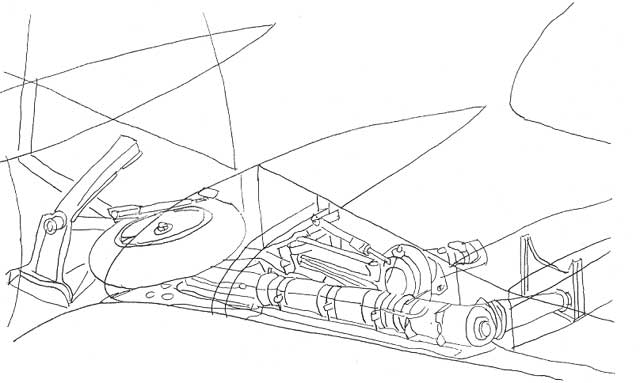

Electric Motor and Folding Drag Links

Photo 3

The

front of the electric located motor in each wing. It is mounted in

the wing spar inboard of the strut/wing attachment point and

provides gear extension and retraction.

A set of folding drag links (Figure # 1 and

Photo 4), also called radius rods, connect the rotating drive outer

cover (front plate) of the electric motor to the landing gear

strut.

|

|

|

|

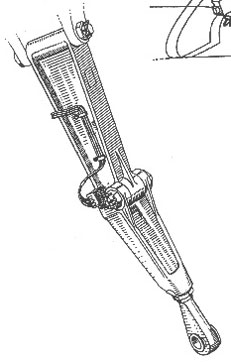

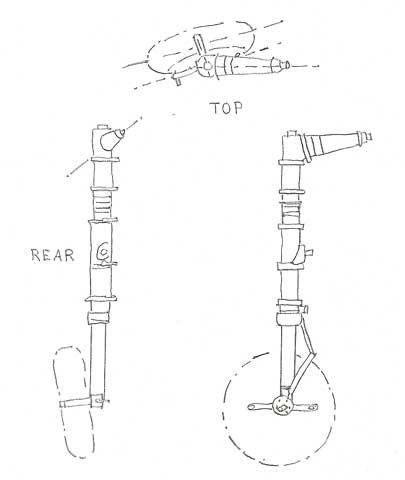

Figure 1 - folding drag link

|

Photo 4 - rear side of landing gear strut showing drag link

attachment point

|

As the electric motor’s face rotates, the

links extend or retract the landing gear (Figure 2 below).

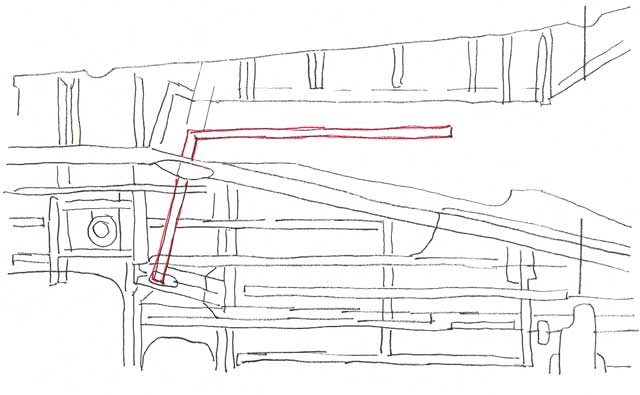

Figure 2

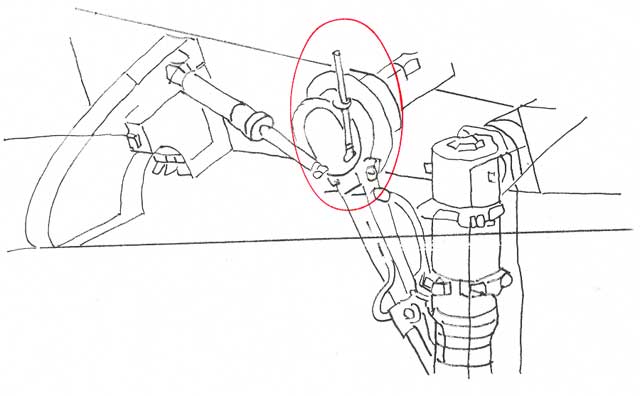

This is also how the visual indicator rod

protrudes from or recesses into the wing top (Figure 3 below) to

inform the pilot that the gear is up or down. The landing gear had

indicators in the cockpit, but this was an additional, machanical

source of position. Usually, the upper ¾ of the rod was painted

red, and lower ¼ painted white. When the gear was extended, and the

pilot saw white on the bottom of the rod, the gear was locked down.

Figure 3

Downlock is provided by electric motor

gearing (1 to 15,000) and a small pressure spring (Photo 5) that

attaches on one end to the rotating face of the electric motor on

the outboard side of the drag link and on the other end to the main

wing spar.

Photo 5

Without this small spring, the gear will

collapse (all modelers detailing their Fw190 wheelwells take note)

as soon as the aircraft is moved and lateral shear is applied to the

landing gear. Uplock is provided by locking units in the wheelwell

that hook onto a small round spur on the aft side of the strut.

Although the gear extends fully for the way

it is designed, it does not extend to a position 90° below the

bottom of the wing. It stops and locks with the gear having an

approximately 13 to14° inward rake as measured from the wing

bottom. This inward rake results in the tire being almost directly

under the electric motor (Figure 4), not the strut attachment

point.

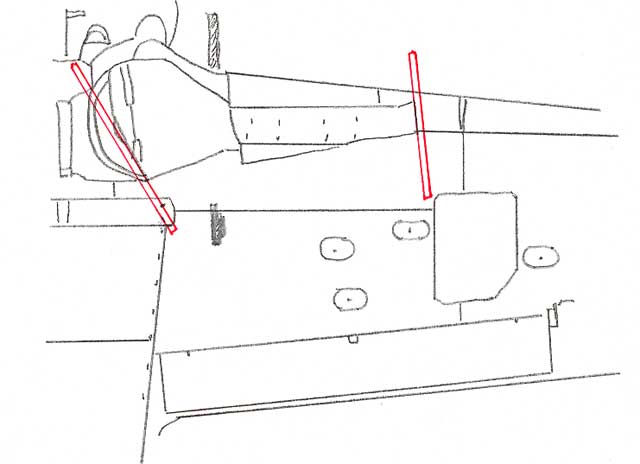

Figure 4

As far as I’ve been able to research the

matter, I know of no definitive answer to the reason for the

gear’s inward rake. You may consider the following while pondering

the design:

a.

The drag links of the landing gear are designed to attach almost ½

the way down the strut. This allows for a very stable strut and

provides great protection from lateral shear. With the size

(length) links they were using, the inward rake may have been

necessary.

b.

Although there is room inside the wing for a larger electric

motor, it may have been decided a smaller and lighter motor, with a

smaller rotating face, could be installed by using shorter drag

links. Don’t think this would have been a bad decision; even the

existing motor, rotating plate, and drag links seem overly strong

for this size aircraft.

c.

Using two points of attachment to the main spar allows the a/c’s

weight to be spread between the strut and electric motor (via the

drag links). This affords dispersal of a/c weight along a section

of the wing spar as opposed to a single point of the wing spar –

which is good. But, the Fw190 main wing spar was rather

over-engineered, so this may not be much of a factor.

Gear & Tire Location

The Fw190 landing gear is located rather

close to the leading edge of the wing. Looking head-on at the wing,

you can easily see the gear cover and especially the tire cover

(Figure 5).

Figure

5 Figure

5

The

reason the gear is located so close the wing leading edge is that it

is in front of the main wing spar, which is the attachment point of

the main landing gear. But, the spar must also allow room in front

for the diameter of the tire. To accomplish this, the main spar

bends forward as it moves toward the wing tip.

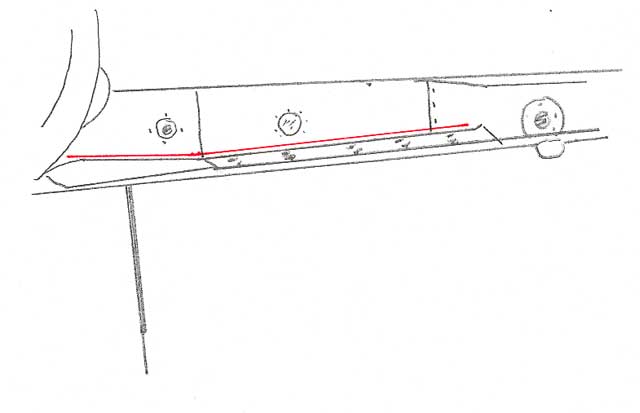

Figure 6 (below) shows the Fw190 upper wing.

The panel line over the location of the aft section of the wheelwell

is the main spar/rear wall of the wheelwell. Note that the panel

line angles forward as it proceeds outward toward the wingtip.

Figure

6 Figure

6

The spar bends forward far enough to provide

attachment of the strut and clearance of the tire while the

landing gear remains perpendicular to the fuselage. This is

different from other wing spar/landing gear configurations of the

time, but it works well.

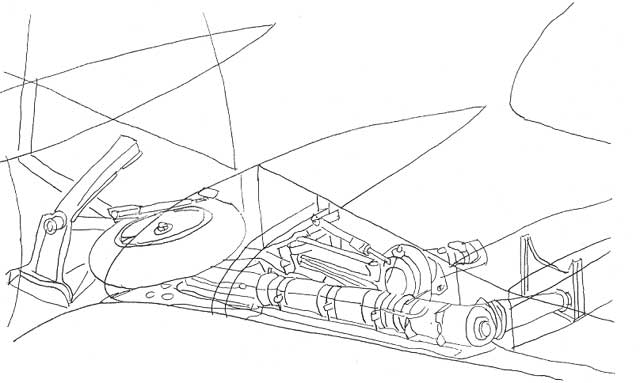

The wing’s leading edge extension at the

wingroot and the wheelwell area through the fuselage allow the

gear’s close position to the wing’s leading edge. When the gear is

in the up position, the strut is stowed inside the wing while the

tire is stowed inside the wing leading edge extension and the

fuselage (Figure 7) - with little room to spare.

Figure 7

[Ever notice that the bottom of the cowling

ammo boxes (Figure 4, right side *), located in fuselage wheelwell

area, are lower at the center of the fuselage than they are toward

the outer edge of the fuselage? That angle is because they were

designed to “just fit” over the retracted main landing gear tire,

which is positioned inside the fuselage at the same angle.]

As I mentioned,

the close location of the gear to the wing’s leading edge, and the

Fw190 wing’s taper toward the tip, moves the tire forward of the

wing leading edge when the main gear is extended (Photo 2). This

forward rake also results from the fact that the strut does not

rotate directly downward from its wing attachment point in the spar.

Strut

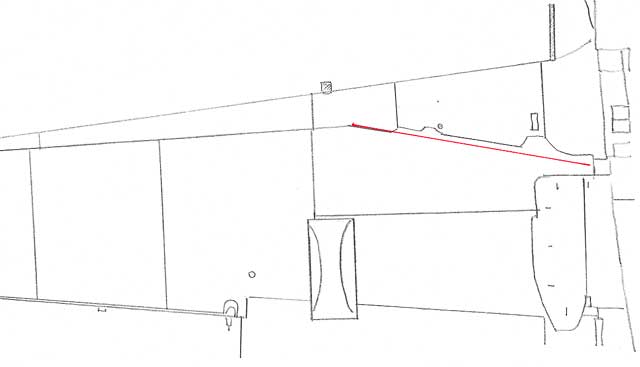

The wing

attachment point at the top of the strut (the bend) is NOT 90° to

the gear leg. The angle is approximately 95°. This slight bend can

be seen in the strut drawings (Figure 8), the arrangement of the

strut attachment point in the wing (Figure 9), and in Photos 6 and 7

of the strut.

Figure 8

Figure 9

Click thumbnails below

to view larger images of Photos 6 and 7:

Further:

1.)

Look at the upper section of the landing gear cover (Figure

10, right side). Notice that the very top of the landing gear

cover, where the strut attaches to the main spar, bents forward.

This bend on the upper portion of the cover fits inside the wing

when the gear extends. The rest of the landing gear cover is

outside the wing when the gear is extended.

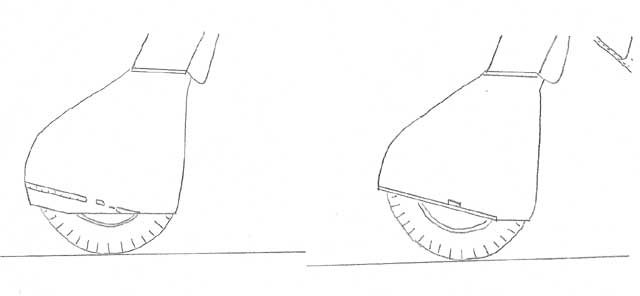

Figure 10

2.)

Look at any photo of a Fw190 on the ground in which you can

see the bottom, aft edge of the landing gear cover (Photo 8).

Notice that the bottom of the cover is cut at an angle parallel to

the ground (Figure 10, left side) when the gear is extended. This

cut is necessary for ground clearance and it varies in size,

depending on Fw190 dash number, and the installation of the inner

gear door (Figure 11). Also notice (Figure 10, left side again)

that this cut is NOT perpendicular to the landing gear strut.

Photo 8

Figure 11

To be Continued

Images

and Text Copyright © 2003 by Robert Stephenson

and

E. Brown Ryle III

Page

Created 18 June 2003

Last updated

19 June 2003

Back to HyperScale Main

Page

Back to Reference Index |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search