|

Focke-Wulf Fw 190

Main Landing Gear

Part Two - 1/48 Scale

Model Issues

by

Robert Stephenson and

E. Brown Ryle III

HyperScale is proudly supported by

Squadron.com

Once Bob got to

work on the specifics of the different manufactures Fw190 model

gear, it quickly became clear that the only way to really settle the

1/48th scale accuracy issue was with actual measurements

of the Fw190 landing gear. I made a phone call to Malcolm Laing.

We needed

measurements that would apply to a model. Simply having Malcolm

measure the gear from end to end or end to wing wouldnít give us

what we needed because of the differences in the way the real gear

installed and the way the model gear attaches.

We settled on a

measurement from the point where the gear leg emerges from the wheel

well to the center of the top link pivot point. We realized that

trying to measure to the axle center would be unreliable. The strut

is compressible and the overall length of the gear would vary

depending on the weight of the aircraft and the internal pressure of

the strut (as prescribed on the pressure chart painted on the

Fw190ís landing gear cover).

At the end of the

week Malcolm provided a hand drawing with the Fw190 landing gear

measurements. I emailed this information to Bob and he took it to

the hobby bench along with his micrometer.

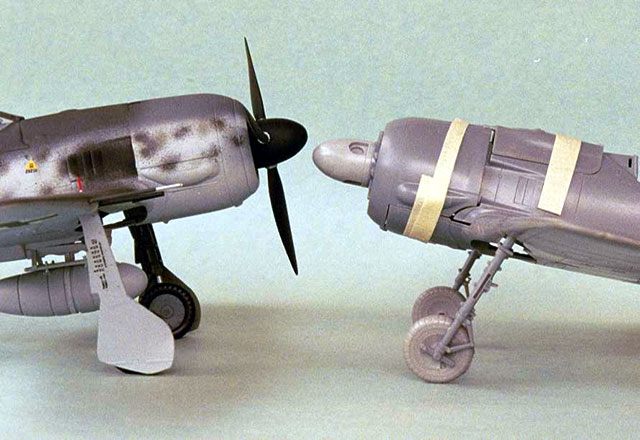

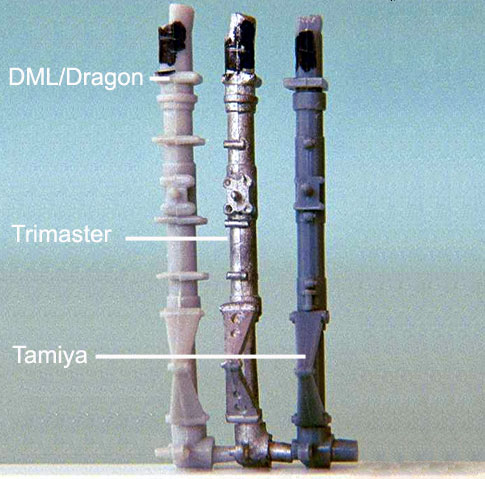

The three 1/48th

scale Fw190 landing gears in question were: the DML/Dragon (L), the

Trimaster, (M) and the Tamiya (R). (Photo 10) I decided to

determine how the gear legs compared with each other, then with our

actual measurements.

Photo 10

I tried to

measure the gear legs in the Fw190 models I had already built. This

method was unreliable. It was too difficult to get my calipers into

position and get repeatable results.

I broke out my

un-built kits and tried another approach. I marked each leg with a

marking pen and installed them in their respective wings. The legs

were marked at the point where they emerged from the wheel well

using a 20x jeweler's loupe and a sharp scriber. I tried to get

reliable measurements by using my calipers but again I considered

the results untrustworthy.

At my job we have

a really cool measuring system that we use to check our close

tolerance work. Basically, itís a microscope/ video/ computer

measuring system. It will magnify a .025 drill bit to about 5

inches on the video screen and measure in three dimensions

calibrated to .0001. By hovering the

crosshairs over the points to be tested and clicking the mouse the

computer will do all the trig or geometry and produce the sizes.

While I didnít use all the available amplification, it did give me

highly reliable measurements:

Wing

Bottom Top Link Retraction Strut

Point Axle Center

Tamiya .786 in.

(19.96 mm) .421 in.

1.179 in.

Trimaster .764 in.

(19.41 mm) .439 in.

1.183 in.

DML .819

in. (20.80 mm) .465 in.

1.226 in.

Real Fw190 .817 in.

(20.75mm)

Included is the

distance from the wing bottom to the center of the axle. This was

done for comparison purposes but because of the reasons listed

above, this distance will be variable on

a real Fw190. The wing bottom to retraction strut point is also

included for comparison purposes.

The DML leg is

almost exactly right. The Tamiya is .031(.79 mm) short. The

Trimaster is .052 in. (1.32 mm) short.

Overall, from

wing to axle, the DML is .047 in (1.19 mm) longer than Tamiya and

.043 in. (1.09 mm) longer than Trimaster. So, why the big

difference in stance when the models are displayed on the table?

There are several factors.

The main reason

for the large difference in the kitís stance lies in the way the

kits are engineered. The Trimaster/DML/Dragon and the Tamiya

landing gears do not assemble the same way.

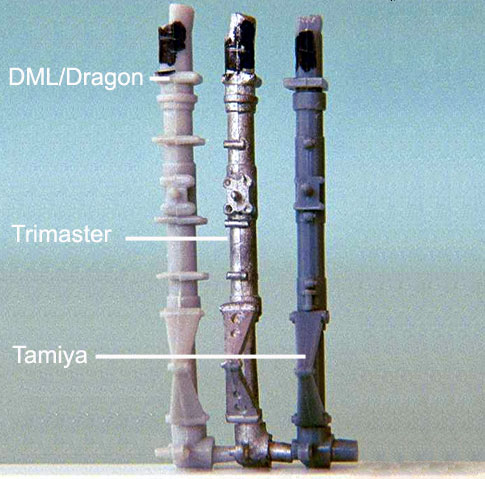

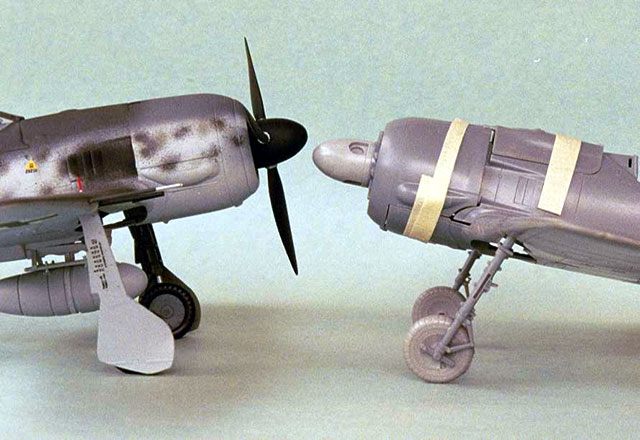

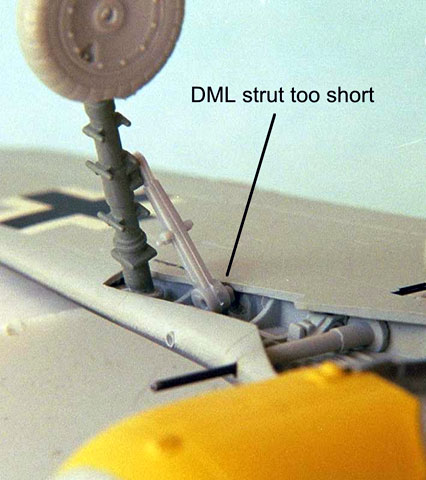

The Trimaster and

DML/Dragon gear have difficulties: When assembled, the legs have

almost no forward rake. Further, installing the DML/Dragon

wheelwell insert can be troublesome and incorrect part placement

will create additional problems. (Photo 11).

As far as we can tell, this DLM/Dragon problem, resulting in

pointy-toe landing gear with no forward rake, is where the rumor got

started about the Tamiya landing gear being short.

DML (no

correction) Tamiya (no correction)

Photo 11

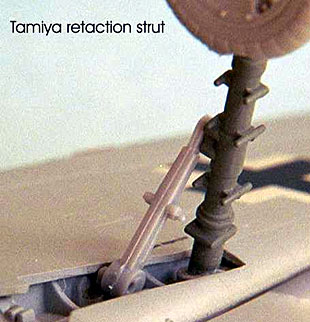

Installed

without any modifications, the gear on the Trimaster and DML/Dragon

hang almost perpendicular to the bottom of the wing. (Photo 12,

TRIMASTER, and Photo13, DML leg) The gear should rake forward about

15 degrees from a line drawn perpendicular to the centerline of the

fuselage. (Photo 14 Tamiya leg)

Photos 12, 13 & 14

As mentioned previously, a good visual

clue that the gear is raked correctly is the bottom of the gear door

should run parallel to the ground. (Photo 15).

DML (no

correction) DML (corrected)

Photo 15

Although the Trimaster gear is metal,

it presents less of a problem than the DML gear. When DML changed

the legs from metal to plastic they also lengthened them. As the

measurements show, this is not really a problem, but the drag link

part that accompanies the DML kit was not lengthened. This does

create a problem.

The

Tamiya gear goes together without much trouble. While this is

great, and Tamiya kits are known for their ease of assembly, not all

of it is cake. The gear stance, if you simply assemble the gear, is

not guaranteed to be correct. You must take your time and ensure

that the gear is aligned to the proper forward rake.

Another

small contributor to the different in kit ďstanceĒ is wheel (tire)

size. Trimaster/DML wheels are .585 in. (14.86 mm) while the Tamiya

wheels are .545 in. (13.84 mm). This means a .020 in (.51 mm)

addition to the Trimaster/DML kits. The correct Fw190 wheel size in

1/48 scale is .574 in. (14.58 mm). So, the Tamiya wheel is slightly

undersized.

Also, all of the

kits are blighted by what resembles a big square knot at the top of

the strut (?). (Photo 10, top of all struts) As itís not on the

real a/c, youíll want to at least reduce it in size for a

better-looking part.

Trimaster

The first thing

you want to do on the Trimaster kit is thin the edge of the wheel

well cut out in the wing. This is simple, gives a more realistic

appearance and helps with assembling the landing gear.

Youíll also have

to do a bit of plastic removal on the outside of the wheelwell

insert for the proper clearance of the upper wing and the wing

leading edge. Test fit the wing halves with the wheelwell in place

until youíve removed enough material for a good fit.

I strongly

suggest you cheat the wheelwell forward a bit. This will allow you

the necessary room, to correctly attach the gear drag links to the

motor face in the main spar. If you position the wheelwell too far

aft in the wing opening, the drag link part will not connect when

you attempt to glue it into place in the wheelwell part. Again,

test fit.

Once you get the

wheelwell to fit into the wing, and moved it far enough forward,

make sure that the sockets for the legs are centered (end to end) in

the opening prior to gluing. You can eyeball this or measure from

the outside edges of the wing opening.

To build the

correct landing gear rake, remove some material from the top back

surface of the strut. Removing this material will allow the strut

part clearance into the socket at the correct angle. While doing

this: try not to remove any material from the very top of the

strut.

As mentioned, the

Trimaster strut is already a bit short. While the Trimaster strut

is a bit too short I donít recommend fixing it. As is, it is only

about .004in (.1 mm) longer than the Tamiya. I donít recommend

lengthening the Tamiya either because if you get the rake correct I

will look just fine, in my opinion. But if you have a terminal case

of AMS follow the recommendations for lengthening the Tamiya strut

further down the page. Just substitute the Trimaster difference for

the Tamiya. It will be a bit more difficult pull off as the metal

legs will be less forgiving of mistakes than the plastic ones.

Use drawings and

photos as a guide as you work on the proper rake of the gear.

Again, a good visual clue that the gear is correctly positioned is

the bottom of the gear door running parallel to the ground. (You

might want to test fit the gear cover occasionally to check your

progress.) For me, this whole procedure is infinitely more

difficult than mating the wings to the fuselage or the cowling to

the fuselage. I just donít have enough hands!

After you have

aligned and attached the gear legs, attach the drag link part. It

will just fit. But, if you find that itís not quite long

enough: follow the up coming notes on the on the DML.

The wheel axle

on the Trimaster is cast at the correct angle. (Photo 16) Just

attach the wheel perpendicular to the ground and align it straight

ahead. But, be sure you metal strut is straight!

Photo

16 Photo

16

DML/Dragon

When DML took

over the molds of the defunct Trimaster Ltd., they redesigned all

the cast metal bits in plastic. So, the new plastic strut is not an

exact copy of the metal strut. It is .043 in (1.09 mm) longer with

the additional length at the very top. (Photo 10 of all three

landing gear). This extra length means that when you correct the

rake in the same manner as mentioned for the Trimaster, the drag

links, which were simply cloned from metal into plastic, will not

reach their attachment point on the aft side of the strut. Photo 17

shows a correctly aligned strut with an un-modified link. Once the

link is attached to the strut, it will no longer attach to the

attachment point in the wheelwell.

Photo 17

The link does not

reach its attachemnt point on the motor face in the wing when the

landing gear strut is properly aligned for the correct Fw190 stance.

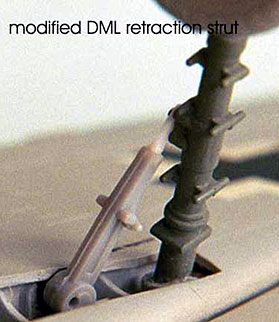

Fortunately, the fix for the DML/Dragon

strut is easy: Cut off the strutís drag link attachment point and

replace it with .045 in. plastic rod that has been flattened on

one end to fit against the strut. (Photo 18, DML original strut

vs. DML modified strut). Test fit for length. This part can be

detailed a bit more than I did for this article, but ďas isĒ; it

looks fine in 1/48th scale.

Unmodified (DML Link) Modified

Photo 18

Using a Tamiya link part on the DML will not provide any more

length than an un-modified DML part (Photo 19). A modified DML

part is required for the correct strut rake (Photo 20).

|

|

| Too Short |

Correct Length |

Photo 19

Photo 20

Unlike the Bf109, the Fw190 wheels run

almost square to the ground (the wheel top leans slightly outward,

depending on oleo pressure). Further, aircraft, like automobiles,

have a bit of camber and toe-in to the tire. The Fw190 was no

exception. These setting were made by various adjustments in the

Fw190ís gear. But, in 1/48 itís too small to be an issue.

The wheel axle on the DML/Dragon is 90į to

the strut. It will incorrectly slant the tire when the strut is

correctly canted inwards. You can simply adjust the tire to the

angle it is supposed to be and CA it in place. Or, you can cut

off the axle, drill a hole that will be parallel to the ground,

and install a .045 in. plastic rod axle. I suggest the axle.

Remember to keep the tires perpendicular to the ground and

parallel to the fuselage centerline.

Tamiya

The Tamiya strut is .031 in (.78 mm) short in

comparison with a real Fw 190 part and .047 in. (1.19) shorter

than the DML overall. Iíll go over a couple of different

suggestions for correcting the Tamiya gear but first I must say

that Iím not too troubled by the fact that the Tamiya gear is

short.

The Tamiya gear is shorter from the top

scissors link to the axle by .014 in. (.36 mm) than the DML gear.

This is only .67 in. (17.1 mm) in 1/1 scale! Iím willing to

accept this difference as a weight /pressure issue on the real

a/c. If you feel the gear needs lengthening here are a couple of

ways to go about it.

To lengthen the strut, cut between the drag

link attachment point and the uplock pin. Remember to calculate

and include the thickness of the saw you are using. If your saw

is .10 in (.25 mm) thick, then add that amount to your overall

correction. This will usually add up to between .040 and .045 in.

(1.02 mm and 1.14 mm).

Sandwich the ďsizedĒ plastic plug between

the cut, check your alignment, and glue. You can strengthen the

joint by pinning it through the center with sections of a small

drill bit or a bit of straight pin.

Another approach is the one taken by

Ian

Robertson in his D-9 build-up (as posted here on Hyperscale).

Briefly, Ian grafted the upper Tamiya strut with the DML scissors

and axle section. Ian did a nice job, and I suggest you check his

article for the complete story. This method will also give you

some additional overall length.

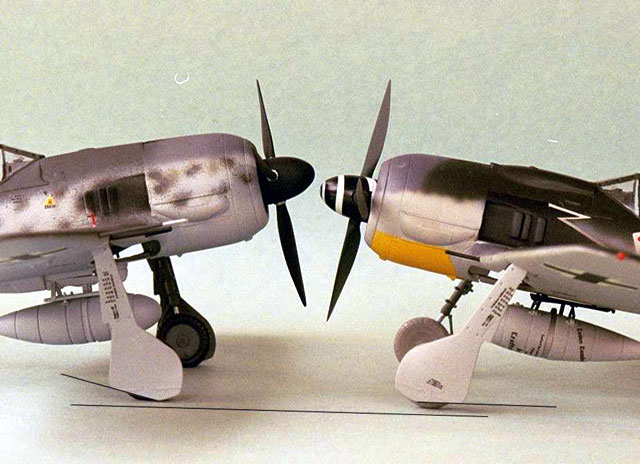

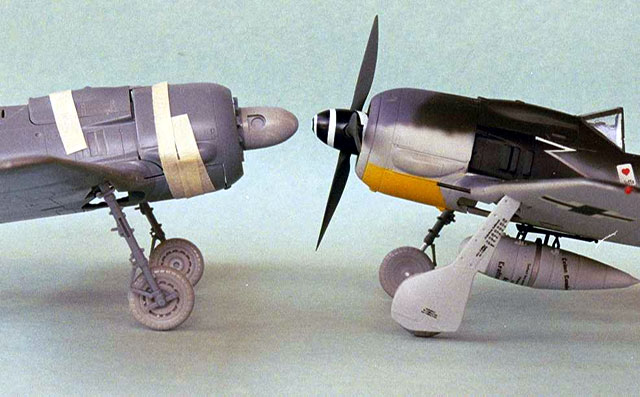

Personally, I donít plan to modify any of

my Tamiya Fw190ís landing gear. There is just not that much

difference when you compare a Tamiya kit to a correctly built

Trimaster/DML kit. And, if you replace the undersized kit

tires with some correctly sized after market ones, that is

about all the help needed with the Tamiyaís stance/height issue.

(See Photo 21, correct tires on Tamiya kit vs. DML kit with

corrected strut)

Tamiya (correct size wheels)

DML (corrected strut)

Photo 21

If

you are not inclined to modify the Tamiya kit, the landing gear

assembles almost trouble free. As when building any model donít

take it on faith that everything will turn out correctly by gluing

parts to their attachment points. Double-check the rake and

inward cant of the gear before making a permanent attachment.

As was said prior: using the gear door as a

guide can help you check the rake and attain the correct stance.

Carefully push and/or pull as necessary.

Another nit-pick item on the Tamiya needing

attention is the wheel axle. It is not parallel to ground after

assembly. Follow the suggestions made to correct the same problem

for the DML/Dragon strut.

|

Gear

Covers - Strut, Attachment and Shape |

One thing that

is not done very well on all the kits is the gear door attachment

studs (Photo #10A). The DML studs are overstated and do not line

up with the holes on the doors. The Trimaster and Tamiya are more

to scale, but are in the wrong position.

Photo 10A

Having said that, Iíll also say that the

placement of the studs may not be much of a problem. On

the real Fw190s the holes on the outside of the doors were usually

patched over with ďpinkingĒ (fabric, glued in place, for

areodynamic reasons) and painted over with a red-brown fabric dope

then RLM 76 (or just the red-brown if the covers had been worked

on).

Another thing

is the shape of the main gear cover. While the outline of all the

covers is not so bad as to disqualify your kit from judging at the

local hobby event, those of you possessing a few good photos of

Fw190 gear covers might want to compare those photos to your kit

parts. A bit of time studying and reshaping quickly provides a

more accurate gear cover.

We hope the

real Fw190 landing gear information has been of help. The landing

gear fixes offered here are easily attained by modelers with

average skill or above average patience and persistence. These

minor gear problem fixes will help modelers achieve an accurate

look to their Fw190 kits.

Thank you for

reading the entire article. Bob and I understand that it might be

overkill for such a specific subject but we hope this information

removes some of the urban legends that have surrounded the Fw190

landing gear and these kits for years.

Happy modeling.

J

The aircraft

and aircraft parts photos are owned by Brown Ryle. The model and

model part photos are owned by Bob Stephenson.

Brown Ryle

completed the line drawings for the figures. Please excuse the

poor quality of the drawings. The pencil drawn lines and the

paper on which the drawings were made did not duplicate well into

electronic medium.

The authors

whole-heartily suggest that the reader obtain copies of the

published references for a much better graphic presentation of the

figureís subject matter.

Fw190 Rivet Manual, dtd 1940

Fw190D Walk

Around

Fw190A/F/G Walk

Around

Return to Part One

Images

and Text Copyright © 2003 by Robert Stephenson

and

E. Brown Ryle III

Page

Created 26 June 2003

Last updated

26 June 2003

Back to HyperScale Main

Page

Back to Reference Index |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search