|

Using Parafilm-M

by David

W. Aungst

HyperScale is proudly supported by Squadron

Ever since my Masking Cockpits

posting, I have received quite a few questions regarding the use of

Parafilm-M for masking cockpit glass. The questions run the full gamut from

"What is Parafilm-M?" to "Can you help me figure out how to use Parafilm-M?".

Parafilm-M has been my weapon of choice for masking canopies for the last ten

or so years. I also will use it for masking over Metalizers. As there is no

adhesive to lift the Metalizer paint off the model, it works great for this.

There are some tricky tendencies to watch for, but overall it is good stuff.

And, it costs considerably less than the five or more dollars that the pre-cut

canopy masks cost. That leaves me with more money to buy after-market goodies

that will still be on the model when I am done.

Armed with my years of Parafilm-M experience and a digital camera, I decided

to see if I could put together a meaningful posting on the use of Parafilm-M.

For continuity, I wanted to use the same model for this entire posting. So, I

had to wait to put this posting together until I had a project up to the point

of getting its canopy masked. The first project to get that honor was not the

normal, run of the mill model, though.

Instead, it is a 1/48th scale die cast metal A-10A Warthog model. I am

painting up several of these metal models as prototypes for a collector's toy

company. After I finish them, the models are shipped to a production facility in

Asia where they will be copied and mass produced. If you see a die cast metal

A-10A in this brown camouflage, know that I did the research and work on the

prototype model that the die cast model is based on.

In building this model, the toy company provided the die cast kit to me. I

was not permitted to modify any of the pieces or even address the seams. All I

could do is construct the kit, paint it, and decal it. As painting and decaling

are probably my two most favorite tasks in modeling, I had fun. And, best of

all, I got paid for the work. Below is a picture of the completed model.

If you wish to see more of this model, I sent some pictures to Two Bobs

Decals for them to place in their model gallery (since it was their decals I

used on the model). You can check them out there.

Now, back to talking about Parafilm-M.

What

is Parafilm-M? What

is Parafilm-M?

Parafilm-M is a waxy plastic film that was created for laboratory use. Its

primary use before the modeling industry found it was for sealing test tubes in

the laboratory. It creates an easy, air-tight seal on test tubes without using

any adhesives that could taint the contents of the test tube. Lacking adhesives

means that it is easy to remove the stuff without leaving any sticky residue.

Parafilm-M comes in rolls, 2 inches wide and several yards long. I typically

use the stuff in one inch segments, so this is quite a supply, even for a very

busy modeler.

Where do you get it?

I cannot answer this directly as the roll I have dates back about ten years.

I bought mine in a hobby shop, packaged on a bubble pack from Testor. As

quickly as I have been using my one roll (I am about halfway though it), I will

not likely need another roll in the next ten or so years. I understand that some

marketing issues forced Testor to stop marketing the stuff, but I could be wrong

about this.

I have been told that Parafilm-M is available from most any laboratory supply

house. If you have friends in the medical business, they likely have access to

it and could get you some. A friend of mine has a mother that works in a

doctor's office. She was able to order a case of the stuff for him (I estimate

that to be a 400 year supply).

What follows are step-by-step instructions on how I use Parafilm-M. When I

bought it, the Testor packaging included instructions, but they would have you

wasting a whole lot of the stuff, so I have amended their instructions and will

related them here.

Some of my usage is based specifically on my work desk design. I custom built

my work desk starting with a five-foot section of kitchen counter top. This

counter top has a rounded front edge that allows me to cut and handle the

Parafilm-M pretty easily. The same instructions can work without the nice

rounded surface, but the technique will vary. I will leave this to you to figure

out.

-

The first step is to cut a small piece of

Parafilm-M off the roll. Testor instructions said to cut about a 4 inch

length. I find that 1 inch is more than enough. See the next steps for why.

Before moving on, though, take care to press the loose end of the Parafilm-M

roll back down. I have found that leaving it unrolled allows it to "dry out"

and it gets brittle, thus making it useless.

-

Remove the protective paper

covering.

-

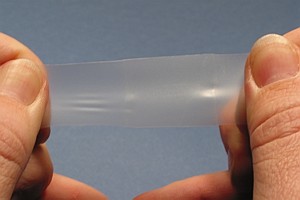

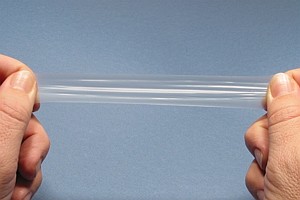

Grip the Parafilm-M firmly at each end and

stretch it in the long direction. A 1 by 2 inch unstretched piece of

Parafilm-M will provide a ¾ by 10 inch piece of ready-to-use Parafilm-M (a

little over 7 square inches). This is why Testor "4 inch" instructions are

excessive. Following their instruction will yield a 1½ by 40 inch piece of

ready-to-use Parafilm-M (about 60 square inches). Besides not having enough

room to work with such a length, I have found most 1/48th scale canopies do

not require more than about four to five square inches of Parafilm-M to cover

them (allowing for some excesses to be cut away). The other 55 or so square

inches in the Testor instructions would get wasted unless you are building

lots of models all at the same time.

Doing this stretching takes a little practise. After a time or two, you get

the hang of it. I will hold the Parafilm-M up as I stretch it so I can see

light through it. As it stretches, the consistency of the Parafilm-M changes.

I continue to stretch until the Parafilm-M is all one uniform consistency (as

seen by the light shining through it).

It is this stretching process that activates adhesive qualities in the waxy

surface of the Parafilm-M. Stretched Parafilm-M will cling with an almost

static-like adhesion to most any smooth, dry surface. The warmth of your

fingers when you press the Parafilm-M into place enhances the adhesion.

|

|

-

After stretching the Parafilm-M, I lay it down

and give it a moment to relax (about ten seconds). Then, I press it down onto

my rounded work desk edge and cut away the unstretched end portions where I

was holding the piece. Any sufficiently sized smooth surface would do for

this. A large piece of clean, smooth sheet styrene would be good. Even a piece

of plate glass (which some modelers use to cut decals) would be fine.

-

Cut off small pieces of Parafilm-M to apply to

the canopy. The size and shape of these pieces is driven by the size and shape

of the canopy I am covering.

The stretchy quality of Parafilm-M is the biggest asset to using it. I have

found no outside corner or shape that it will not cover. Even if it folds over

on itself a little, the seal on the canopy remains tight -- just press it

down. You can further stretch it as you apply it to the canopy. Be warned,

though, that as you stretch it more, it gets extremely thin. The point where

it rips is easily reached if you are not careful. It is also possible for it

to stretch to the point of becoming porous and thus not masking the canopy

very well any more. My advise is to not stretch it too much after the initial

stretch.

-

Cut away the excess Parafilm-M from the edges of

the canopy.

Important! -- Parafilm resists being cut unless two things

are both true:

-

The knife you use must be extremely sharp,

such as a brand new X-acto blade.

-

The Parafilm must be fully against the

canopy surface.

If either of these conditions is not true, the

Parafilm-M will not cut cleanly. It will drag and deform as it is cut. The

sharp blade is pretty easy to get right, just replace the blade in your knife

before you start cutting. The part about keeping the Parafilm-M fully against

the surface is not always so easy. Inside corners can be almost impossible to

get the Parafilm-M to go into. The Parafilm-M adheres to most any tool I have

tried for pushing the stuff into inside corners. When I pull the tool away,

the Parafilm-M lifts away with the tool instead of remaining in the corner

that I just pressed it into.

I will resort to Scotch brand Magic Transparent

tape for doing tight inside corners as Parafilm-M does not do these well. I

have had no trouble combining the use of tape and Parafilm-M on the same

model. Apply the tape first, than fill and finish the masking with Parafilm-M.

-

With all the canopy portions masked and the

Parafilm-M trimmed, I will paint, apply decals, and weather the model. You are

on your own with these processes.

-

Remove the Parafilm-M.

The length of time on the model and the types of paints you use will effect

how easily Parafilm-M will come off the canopies. I use some pretty potent

paints (enamels and lacquers thinned with Xylene) and I tend to leave the

Parafilm-M on the model for upwards of a month (on average) as I do not unmask

the canopies until after I complete weathering. This combination leaves the

Parafilm-M pretty tight on the canopy. This is good as no paint gets under the

Parafilm-M. It took me some time, though, to figure out how to easily remove

it.

What I use that seems the easiest with the least damage to anything is a short

strip of Evergreen styrene (0.100 by 0.080 inch cross-section and about 4

inches long). I file one end to a chisel point and use this to scrape off the

Parafilm-M. As the Evergreen styrene is softer than the canopy, no scratching

occurs. And the paints I use are tough enough to not get damaged by the

scraping, either. I believe that if you use less potent paints, like water

based acrylics, the Parafilm-M comes off much easier. But, I have never tried

testing this.

When I mask Metalizers, I usually only have the stuff on for less than one

day. Even using the lacquer-based Metalizers, the Parafilm-M comes off easily

after just lifting one corner with the tip of a knife.

So there you have it. A step-by-step approach to using Parafilm-M.

I have not included many pictures of completed models in this posting as you

can find those elsewhere on this site. Almost every model I have on this site

has had its canopy (and any natural metal) masked by using Parafilm-M.

Text & Images Copyright ©

2002 by David W. Aungst

Page Created 29 April, 2002

Last Updated

19 April, 2004

Back to Reference Library

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search