|

Building

Vacform Models

Part

One - The Basics

by Brett T. Green

|

Meteor

F.8

Aeroclub Vacform 1/48 Kit |

See also

"Gloster

Meteor F.8", a Construction Feature on HyperScale, for a detailed

description of a vacform modelling project.

Why

Build a Vacform Model?

Modellers

today are presented with a breathtaking choice of kits. Most major aircraft,

armour and car subjects are already available in injection moulded form. Very

little effort is required to build a great looking model.

However, the peculiar nature of many modellers is that we often want to build a

very specific subject. Sometimes we want to build something because it is not

available in mass-produced form. Others may simply wish to rise to a new

challenge.

Technological

advances have not been limited to the injection-moulded model industry. Vacform

models have made stupendous leaps in quality and detail in the last ten years.

Vacformed parts now feature surface detail to rival the major manufacturers.

Many vacform kits are now multi-media masterpieces with brass etched parts,

white metal and resin adorning the basic plastic.

And

if you want to build a Barracuda, a Firefly, a Hudson or a Caribou in 1/48

scale; or a Boomerang in 1/32 scale; there is only one game in town – vacform!

What

is Vacform?

Vacuum

Forming (vacform) is an inexpensive method of producing basic shapes on sheet

plastic.

A

master pattern is first built by a pattern maker. A female mould is then created

from the master, Finally, heat and suction is applied to flat sheet plastic to

produce a raised impression of this female mould. The limitations of this method

mean that it is not possible to replicate undercuts and some complex shapes.

The

modeller is left with the task of cutting the parts off the sheet and cleaning

them up for assembly.

The

big benefit of vacforming is that big tooling costs are avoided, making it

practical to produce a short run of esoteric subject matter that would not

otherwise be available.

What

Vacform Model Should I Start On?

I

recommend a conversion for a first attempt at vacform modelling.

Falcon

produce a number of “Triple Conversion Sets” including Spitfires, Bf 109s

and a number of Century Series jets. Sierra Scale Models also produce a very

high quality Wirraway conversion.

These

conversions contain a small number of parts (usually two fuselage halves, a

canopy and some details) making them an ideal introduction to this media.

The Falcon and Sierra conversions are still in production.

If

you really want to tackle a full kit, then select your first model from the list

of “High Tech / High Quality” manufacturers below.

Hi

Tech/High Quality?

The

finished product from any of the following manufacturers will match the standard

of many injection-moulded kits. These companies usually supply smaller detail

parts in injection-moulded plastic, resin or white metal. The modeller is not

required to fabricate many (or any) detail parts. Instructions and decals are

typically included.

The

following list of manufacturers is not comprehensive, but is a starting point:

|

Dynavector

|

|

PP

Aeroparts

|

|

Sierra

Scale Models

|

|

Aeroclub

|

|

Falcon

(later releases)

|

|

Karo

As

|

|

MPM

|

|

Koster

|

|

Aircraft

in Miniature (1/72 Scale Civil Subjects)

|

|

FM

(Australian company – 1/32 scale Boomerang)

|

|

OzMods

(Australian company - 1/48 scale Caribou)

|

"DIY"

Kits

There

is another category of kits that should not be attempted by the beginner.

They

are typified by companies like ID Models. The modeller is presented with nothing

but a few sheets of vacform plastic. Features such as landing gear and cockpits

must often be built from scratch. Surface detail may be soft, or missing

altogether. And decals? What are they!

Although

these kits are not for the feint hearted, they do fill a niche for modellers who

have very specific interests. Despite their very basic nature, they are better

than nothing. However, the modeller should have experience of vacform modelling

and scratchbuilding before commencing this style of project.

| Building

a Vacform Kit - The Basics |

The

Tools

As

with any modelling project, an appropriate set of tools is essential.

The

biggest difference between vacform modelling and building a conventional

injection-moulded kit is the preparation of the parts. Specific tools required

for parts preparation are available inexpensively from the local Supermarket or

Hobby Shop.

Here

is my suggested checklist of tools for dealing with vacform parts:

|

Tool

|

Purpose

|

|

Hobby

Knife with Several New Blades

|

General

cutting and cleanup.

|

|

Hobby

Knife with Several New Blades

|

General

cutting and cleanup.

|

|

Scriber

|

My

preference is an Olfa P-Cutter (also available as a Tamiya Scriber).

This tool is an alternative to a knife for removing large vacform parts

from the sheet. It may also be used to restore or improve surface detail

on plastic parts.

|

|

30cm

Steel Rule

|

Essential

for measuring and cutting straight edges.

|

|

Pencil

or Black Marker

|

For

marking edges and part descriptions

|

|

Scissors

|

A

sharp, strong pair of scissors. Handy for cutting excess from plastic

sheets

|

|

Side

Cutters

|

For

“nibbling” around small vacform parts before final cleanup.

|

|

Pin

Vice

|

With

drill bits for drilling locating holes.

|

|

Emery

Boards

|

Disposable

nail files. I find these cheap files indispensable.

|

|

Nail

Buffing Stick

|

For

final polish.

|

|

Glasspaper

|

Various

grades of paper from around 400 grit to 2000 grit

|

|

Sanding

Block

|

Either

a small block of wood, or a reusable sanding block such as the Sandvik

“Handy Sander”.

|

|

Liquid

Glue

|

For

a strong bond between vacform parts with no locating pins.

|

|

Super

Glue

|

To

bond small metal or resin detail parts (super glue should not be used

for parts under load).

|

|

Epoxy

Glue

|

To

secure multi-media parts under load (eg undercarriage)

|

|

Tape

|

I

use various widths of Tamiya masking tape for many tasks including test

fitting and securing parts while glue dries.

|

|

Two-Part

Epoxy Putty

|

My

preference is Milliput White. The grain is very fine, it stays workable

for at least 30 minutes and it is easy to shape on the model. Doesn’t

smell either.

|

|

Surface

Putty

|

Mr

Surfacer or similar will ensure a smooth, blemish-free finish.

|

|

Putty

Trowels

|

Nothing

fancy – I use a staple remover (my favourite), old knife blades and

ice-cream sticks.

|

|

Tweezers,

Pliers and Clamps

|

For

handling and holding small items.

|

Getting

Started

It

is important to follow recommended assembly

sequence and instructions in this style of kit. If instructions are supplied,

read them! Familiarise yourself with the instructions and identify all the parts

before you start.

Preparing

the Parts

I

follow a set sequence when preparing vacform parts:

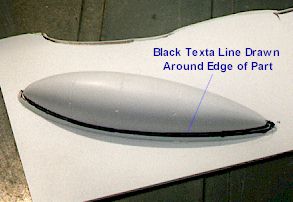

- 1.

Draw Around Parts – Take your marker or pencil and

draw around the outline of all the parts, making sure that you get

into the edge where the part meets the sheet. Don’t worry if the

line is thick.

|

|

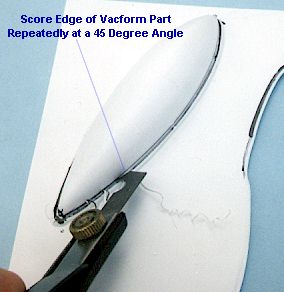

2.

Scribe Around Parts – Now take the scriber and

score, lightly at first, all around the parts. Hold the scriber at 45°

angle to the part (see picture). Don’t leave a border – scribe right

up against the part. Repeat the scoring until the scriber has nearly cut

through.

|

|

3.

Remove Parts From Sheet – Use your scissors to

cut a section of the backing sheet around the part away from the main

sheet. Next cut some “channels” into the backing sheet toward the

part. You’ll need more “channels” on curved parts. Now simply snap

off the backing sheet from the part.

|

4.

Clean Up The Part – You will be left with a part that

has a black line around its edge (that you marked earlier), and a thin

wedge of plastic below the line. The black line indicates the limit of

sanding. Don’t sand above this line! Use a sanding block or a large,

coarse nail file to sand off the excess and check your work regularly.

Keep the sanding block wet while working – it’ll make it easier to

clean up later.

|

| 5.

Thin Trailing Edges – Generally, trailing edges will

need more attention even after the excess plastic has been removed by

sanding. I find that sanding trailing edges is tedious and inefficient.

Try using the back of a hobby knife blade to scrape the inside surfaces

of trailing edges to achieve scale thickness. |

Getting

Ready to Assemble

Vacform

parts don’t have any locating pins so extra care must be taken to ensure

correct alignment.

Tape

major assemblies together to find any problem areas, then work out a plan to

deal with them.

It

is sometimes helpful to add small rectangles of scrap plastic sheet as locating

tabs for parts with a fairly straight, flat join (eg fuselage halves and engine

nacelles)

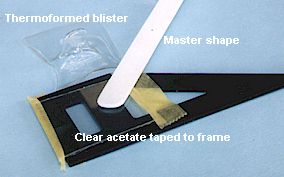

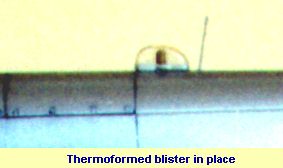

Thermoforming

Thermoforming

allows small parts to be custom-made. No special equipment is required. This

method is useful for creating replacement canopies of small, simple shapes.

Follow these steps:

|

|

1.

Master - A simple master can be made from plastic,

balsa or metal.

2.

Frame - A frame should be made up with a hole big

enough for the part.

3.

Preparing for Thermoforming - A sheet of white styrene

or clear acetate should be secured to the frame. I usually tape the

plastic to the outside edges of the frame. Use fairly thick plastic as

this method stretches (and therefore thins) the produced part.

4.

Taking the Plunge – Hold plastic in the frame over a

candle until the plastic softens. Don’t hold it too close and make

sure you have a bucket of water in case the plastic catches fire! When

the plastic is soft, plunge the master into the plastic and through the

frame. Immediately remove the plastic from the heat source. You may even

wish to dunk the part in water at this point.

5.

Do It Again – This is a trial and error method. You

probably fouled up the first time! Try again until you are happy with

your replacement part. |

Filing

and Sanding

Vacform

modelling usually leaves more gaps and joins than a corresponding injection kit.

My method of filling and sanding a vacform is as follows:

1.

Main Filling – I like Milliput for a number of reasons. As a

two-part epoxy putty it adds structural strength to the model. It isn’t just

sitting between a gap. It is also very pliable and stays that way for a long

time. The grain is extremely fine and it is also easy to sand, wet or dry. The

key to using Milliput is in the mixing. I never mix pieces that are bigger than

half the size of a pea. This allows me to rub the two parts briskly between my

palms until it is a thin snake of putty, then roll it up into a ball and repeat

several times. The warmth of the friction improves the pliability too. Apply the

thoroughly mixed putty to gaps, and shape with a wet finger or a putty trowel.

2.

Sanding – When the Milliput is dry, start lightly sanding

with 600 grit paper. Don’t go too heavy – vac-form material is softer than

injection moulded plastic and it scars easily. Use progressively finer grades

until a smooth finish is achieved

3.

Finishing – The main disadvantage of using Milliput on

vacforms is that the putty is white and the plastic is also usually white. This

makes it difficult to ensure that all the tiny gaps are filled. I therefore

brush on a coat of “Mr Surfacer 1000”, followed by a light sanding. This

helps achieve a perfect finish.

Building

a vacform model can be rewarding because it introduces new skills and can open

doors to a range of otherwise unavailable subjects.

Don’t be afraid to stretch yourself and test

some of these new techniques – you never know where it might lead!

Images, Text and Model Copyright © 1999 by Brett Green

Page created on 25 August, 1999

This page last updated on

12 May, 2002

Back to The Reference Library

Back to HyperScale Home Page

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search