|

Late-War Bf 109G/K in Detail

Part One

Cowl Bulges for DB 605AS series & D Powered Bf 109s

Photographs by Evergreen Education Facility (via Bob Rinder)

Descriptions by Brett Green

|

Messerschmitt

Bf 109G-10

under restoration at Ft. Collins for the Evergreen Education Facility

Photo: Copyright © 1998 Evergreen Education Facility; Robert Rinder and Mike Conner |

Part One of "Messerschmitt Bf 109G/K in

Detail" focuses on the contentious area of the conformal bulge.

The so-called "bulged" cowling was required

to accommodate the larger supercharger, engine bearers, struts and pipes associated with

the DB605AS/ASM/ASC and DB605D series of engines.

Bob Rinder and Mike Conner have kindly allowed

HyperScale to reproduce these excellent photographs to provide a unique insight into this

difficult subject. We are also grateful to John Beaman and Dr Charles Metz for their

comments and assistance.

Part Two illustrates

this interesting feature with six additional photographs courtesy of David Lake.

The "Captain Michael King Smith Evergreen Education Centre" in Oregon USA

commissioned the restoration of this interesting aircraft. It can be traced as a Bf

109G-14 that was rebuilt as a Bf 109G-10 with the new werknummer 610937.

This werknummer is consistent with a Bf 109G-10 equipped with a DB 605DC

engine.

For more information and photographs of the completed restoration, you can visit the

"Captain Michael King Smith Evergreen Education Centre" website by following this link.

The various styles of late-war Bf 109 "conformal" engine cowlings and

fuselage fairings have been described in detail by M. Jean-Claude Mermet in his

self-published book, "Les Messerschmitt Bf 109 G-1 a K-4 - Moteurs et

Amenagements", and also in Issue Number 13 of "Luftwaffe Verband" (January

1998). He describes a number of structural features which identify the cowl as either Type

090, Type 100 or Type 110. The latter type of cowl has a wide, shallow oil cooler intake,

a flatter bottom cowl with no "cheek blisters" and a rectangular fairing

(replacing the curved style) on the port side fuselage under the windscreen. It should

also be noted that there are some variations within these designations.

The forward fuselage of the restored aircraft is consistent with most of the features

of a Type 100 engine cowling. The style of gun troughs, the panel lines, position of

operational filler hatches, the deep oil cooler and the lower forward cheek bulges all

confirm this identity. However, there are a few mysterious omissions mentioned in the

pictorial. Although it seems that there is almost no such thing as a "standard"

Bf 109G-10, this is pretty close.

We are therefore provided with a unique opportunity to see the true profile of the

somewhat elusive "asymmetrical cowl bulge". The following ten photographs

illustrate the asymmetrical, subtle and complex nature of the late Bf 109 engine cowl.

| T

h e P i c t o r i a l . . . |

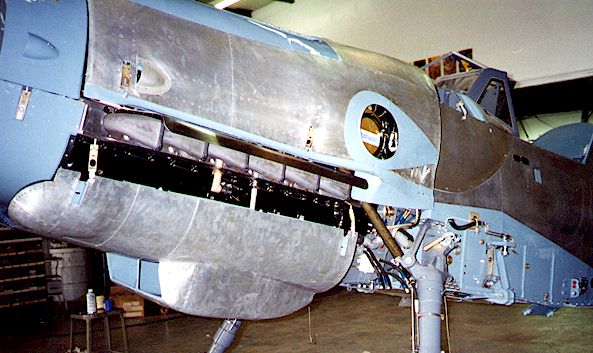

| Image 1: Firewall Looking

more like a science fiction robot, this shot of a Bf 109G-10 firewall provides a good idea

of the different shaped bulges on the Port and Starboard sides.

Note the light blue attachments to the side of the upper firewall. These are the

internal covers for the fuselage fairings behind the cowl bulges.

See how the Starboard profile (on the left side of this photo) is much flatter

than the Port side, which is both wider and curved outward. This complex curve curve

extends further out as it travels forward on the engine cowl. |

|

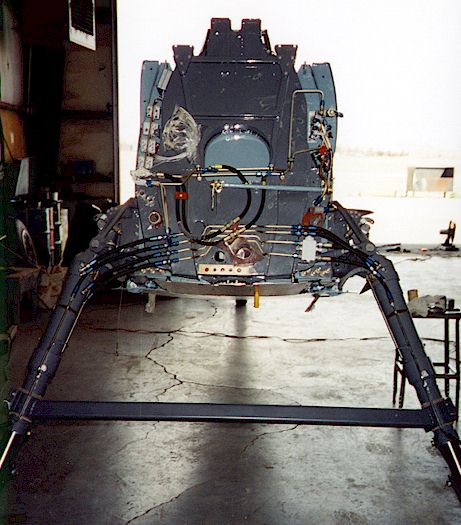

| Image 2: Port Side Cowl The

Port side cowl exhibits all the features expected in a Type 090 or Type 100 cowling -

namely the shorter, pressed insert and the forward vertical panel line.

The curve of the bulge is also clearly illustrated at the back edge of the cowl.

The continuation of the bulge to a position somewhere forward of the

supercharger intake hole (then tapering off until the vertical panel line) can also be

made out with the help of the reflections on the shiny metal and the backward angle of the

hole itself.

Note that the cowl halves are slightly splayed. |

|

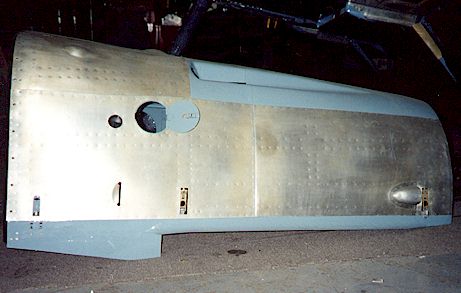

| Image 3: Starboard Side

Cowl Starboard cowl looks closest to a Type 100 - the access hatch to the

cold weather starter is in the higher position. On a Type 100 cowl the old access hatch

should be present immediately below the new. It was usually welded shut. However, there is

no evidence of the lower access hatch on this example.

The Starboard side cowl is clearly not nearly as curved or complex as the Port

side. It is, in fact, quite a simple fairing with an almost flat, vertical appearance at

the back of the cowl.

In summary, then, the sides are asymmetrical. |

|

| Image 4: Port Cowl In

Place The Port cowl viewed from this angle demonstrates the continuation

of the bulge to near the top of the cowl, behind the port machine-gun trough. This bulge

covered the larger curved engine mount, itself required to clear the larger supercharger

of the DB605 AS and D series engines.

Also clear in this view is the deep oil cooler and the oval shaped

"bump"at the corner of the lower cowl. Note the distinct "step" at the

front and rear of the oil cooler. It is slightly odd that the oil filler cap on the cowl

ring in the lower position is missing altogether. It should be welded shut, just above the

forwardmost scoop. |

|

| Image 5: Port Side Mid

Fuselage A good shot of the fuselage fairing typical of Type 100

cowlings. This illustrates how the fairing is simply riveted to the fuselage side. Note

the small, triangular fairing similarly attached under the side of the windscreen.

Once again, reflections highlight the complex angles of the Port side cowling,

and the extreme nature of the bulge. |

|

| Image 6: Starboard Cowl

- Side View Straight side view of the Starboard cowling. |

|

| Image 7: Inside of Port

Cowl and Port Wingroot Panel Note the big kink in the upper leading edge

of the Port Wingroot Panel, and the corresponding kink in the Port Side Cowling

immediately under the hole for the supercharger intake.

There is no kink on the Starboard side. |

|

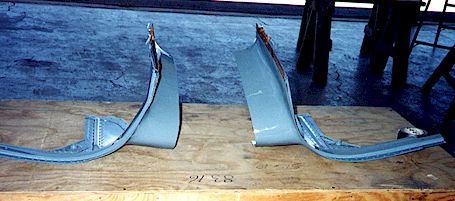

| Image 8: Wing Root

Fairings It is clear that the cowl intrudes significantly over the Port

Side Wingroot Panel (left side of photo). Note the difference between the Port and

Starboard sides when viewed at almost the same angle. |

|

| Image 9: Port Side

Wingroot The Wingroot panel fits right here. The front of the panel goes

right under the supercharger, with the panel extending back to cover the gap between the

port wing and fuselage side.

Note the temporary cover on the supercharger intake.

The wing has not been installed. |

|

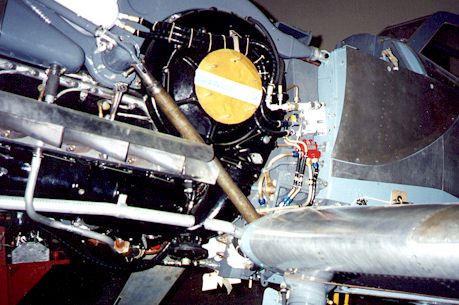

| Image 10: Supercharger The

wing has been installed in this photo.

And here is that big supercharger. A portion of the curved upper engine mount

may also be seen in the top of the picture. |

|

HyperScale visitors interested in the colours, markings and origins of another late-war

Bf 109 may wish to see the "Late-War Luftwaffe Fighter

Camouflage" series on this site. Part One examines

the origins and colours of Bf 109G-6 werknummer 163824, at the Treloar Technology

Centre of the Australian War Memorial.

Mermet, Jean-Claude, "The Messerschmitt Bf 109G-10", article on pages 22-27

of Luftwaffe Verband magazine, Issue Number 13, January 1998.

Mermet, Jean-Claude, date and ISBN not quoted. "Les Messerschmitt Bf 109 G-1 a K-4

- Moteurs et Amenagements". Self Published by the Author.

Evergreen Education Facility Web

Site - historical background on Wnr 610937

Photographs Copyright © 1998 by Evergreen Education Facility; Robert Rinder and Mike Conner

Text Copyright © 1998 by Brett Green

Page created on Thursday, October 08, 1998

This page last updated on Thursday, May 09, 2002

Go to Part Two of "Late War Bf

109G/K in Detail"

Back to The Reference Library

Back to HyperScale Home Page

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search